Cov Pob Li Qub Siv Rau Dab Tsi?

Cov pob valve yog cov khoom tseem ceeb hauv cov txheej txheem tswj cov kua dej, uas paub zoo txog lawv qhov kev ntseeg tau, kev hloov pauv tau yooj yim, thiab kev ua haujlwm zoo thoob plaws hauv kev lag luam. Txij li cov kav dej hauv tsev mus rau cov roj hauv hiav txwv tob, cov quarter-turn valves no ua lub luag haujlwm tseem ceeb hauv kev tswj cov kua dej, cov pa roj, thiab txawm tias cov khoom siv khov kho. Hauv phau ntawv qhia no, peb yuav kawm txog seb cov pob valve ua haujlwm li cas, lawv cov txiaj ntsig tseem ceeb, cov ntawv thov feem ntau, thiab cov qauv yav tom ntej - muab kev paub rau koj xaiv thiab siv lawv kom zoo.

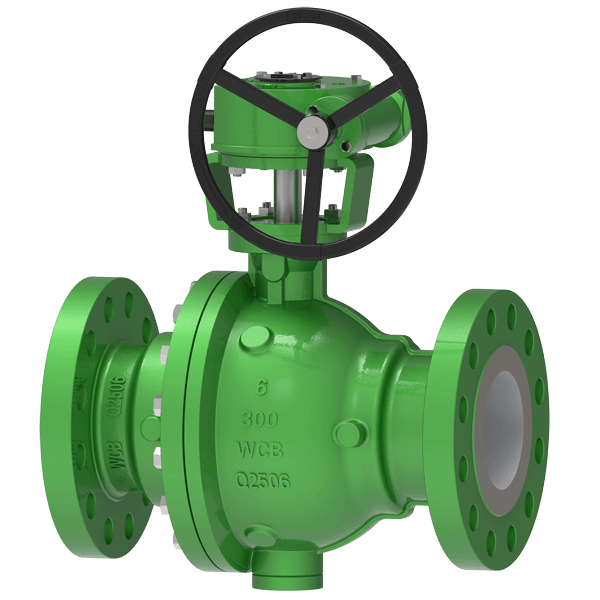

Yuav Ua Li Cas Pob Valves Ua Haujlwm

Hauv lawv lub plawv, cov pob valve ua haujlwm ntawm ib txoj kev yooj yim tab sis zoo: ib lub disc spherical uas tig (lub "pob") nrog lub qhov (qhov) hauv nruab nrab tswj cov dej ntws. Lub valve ua haujlwm nyob ntawm peb yam tseem ceeb: lub cev valve (uas muaj cov khoom sab hauv thiab txuas rau cov kav dej), lub pob perforated (lub plawv uas tswj kev qhib thiab kaw), thiab lub qia (uas xa lub zog tig los ntawm lub actuator mus rau lub pob).

Thaum lub pob lub qhov sib dhos nrog cov kav dej, lub valve qhib tag nrho, cia cov dej ntws tsis muaj dab tsi thaiv. Tig lub pob 90 degrees (ib feem plaub tig) tso qhov khoom khov kho ntawm lub pob hla txoj kev ntws, kaw cov dej ntws tag nrho. Kev ua haujlwm tuaj yeem ua tes (los ntawm lub lever lossis handwheel) lossis tsis siv neeg (pneumatic, hluav taws xob, lossis hydraulic) rau kev tswj hwm chaw taws teeb lossis kev tswj hwm meej. Ob qho qauv tsim ua rau muaj kev siv tau ntau yam: cov pob valve ntab (qhov twg lub pob txav me ntsis thaum muaj kev nyuaj siab kom kaw) thiab cov pob valve uas tau teeb tsa los ntawm trunnion (qhov twg lub pob tau khi los ntawm cov qia sab saud thiab sab qis rau kev siv siab).

Cov txiaj ntsig tseem ceeb ntawm kev siv lub pob valve

Cov pob valve sawv tawm ntawm cov kev daws teeb meem tswj cov kua dej rau lawv cov kev ua tau zoo thiab cov txiaj ntsig ntawm cov neeg siv:

- Qhib thiab Kaw Sai: Kev tig 90-degree ua tiav tag nrho cov voj voog qhib/kaw hauv tsawg li 0.5 vib nas this, ua rau lawv zoo tagnrho rau cov xwm txheej kaw thaum muaj xwm txheej ceev xws li cov tshuab hluav taws lossis cov roj xau.

- Kev Sib Nqus Zoo Tshaj Plaws: Cov qauv mos-seal (PTFE) ua tiav kev sib khi ua npuas ncauj (kev xau ≤0.01% KV), thaum cov qauv tawv-seal (hlau) tswj kev ntseeg tau hauv cov xwm txheej siab / kub siab - tseem ceeb rau cov xov xwm uas yooj yim hlawv thiab tawg lossis corrosive.

- Kev Tiv Thaiv Dej Tsawg: Cov pob valve puv nkaus muaj qhov sib npaug rau txoj kab uas hla ntawm cov kav dej, ua rau muaj kev poob siab tsawg kawg nkaus (qhov tsis kam coefficient 0.08-0.12) thiab kev txuag hluav taws xob rau cov kab ke loj.

- Kev Ruaj Khov thiab Kev Siv Tau Ntau Yam: Tiv taus qhov kub thiab txias ntawm -196 ℃ (LNG) txog 650 ℃ (cov cub tawg kev lag luam) thiab kev siab txog li 42MPa, hloov kho rau cov kua, roj, thiab cov khoom me me xws li slurry.

- Kev Kho Yooj Yim: Cov qauv tsim modular tso cai rau kev kho hauv kab (tsis muaj kev rhuav tshem cov yeeb nkab) thiab cov foob hloov tau, txiav lub sijhawm kho los ntawm 50% piv rau cov qhov rooj vag.

Cov Kev Siv Dav Dav ntawm Pob Valves

Cov pob li qub muaj nyob thoob plaws hauv kev lag luam, ua tsaug rau lawv qhov kev hloov pauv mus rau ntau yam kev ua haujlwm:

- Roj thiab Roj Av: Siv rau hauv cov kav dej roj nyoos, kev faib roj av, thiab LNG terminals—cov pob valve ruaj khov tswj kev sib kis siab, thaum cov qauv welded haum rau kev teeb tsa hauv av.

- Tshuaj lom neeg thiab tshuaj: PTFE-lined lossis titanium alloy pob valves tswj cov kua qaub, cov kuab tshuaj, thiab cov kua dej huv, ua tau raws li cov qauv kev huv rau kev tsim tshuaj.

- Dej thiab Dej Khib Nyhiab: Cov twj tso kua dej uas ntab dej tswj kev faib dej hauv nroog thiab kev kho dej phwj, nrog rau cov qauv V-port uas tswj cov dej khib nyiab uas muaj cov khoom khov kho los ntawm kev txiav.

- Lub Zog thiab Lub Hwj Chim: Tswj cov dej pub rau boiler, cov dej ntws, thiab cov tshuab cua txias hauv cov chaw tsim hluav taws xob thermal thiab nuclear - cov hlau sib xyaw kub siab tiv taus cua sov heev.

- Khoom Noj thiab Dej Haus: Cov pob valve huv uas muaj sab hauv du thiab tsis muaj qhov tawg tiv thaiv kev ua qias tuaj hauv kev ua kua txiv, kev tsim mis nyuj, thiab kev ua npias.

- Chaw Nyob thiab Chaw Lag Luam: Cov pob valve tes kaw cov kav roj, HVAC systems, thiab cov kav dej, thaum cov qauv hluav taws xob ua kom tswj tau qhov kub hauv cov tsev ntse.

- Kev Lag Luam Tshwj Xeeb: Kev tsav dav hlau (roj systems), marine (offshore platforms), thiab mining (slurry transport) vam khom cov qauv tsim rugged rau cov chaw ib puag ncig hnyav.

Ntau Hom Pob Valves

Cov pob li qub raug faib ua pawg los ntawm kev tsim, qhov loj ntawm qhov chaw nres nkoj, thiab kev ua haujlwm, txhua tus tau tsim rau cov kev xav tau tshwj xeeb:

Los ntawm Ball Design:

- Cov Pob Li Qub Uas Nthuav Tau: Pob "nthuav" los kaw lub rooj zaum - yooj yim, pheej yig rau qhov siab qis mus rau nruab nrab (DN≤50 cov kav dej).

- Cov Pob Li Qub Uas Muaj Trunnion: Pob tau khi los ntawm trunnions—torque qis, zoo tagnrho rau kev siv siab (txog li PN100) thiab txoj kab uas hla loj (DN500+).

- V-Port Ball Valves: Lub qhov V-puab rau kev kaw kom raug (qhov sib piv kho tau 100: 1) thiab kev txiav - zoo meej rau cov khoom siv viscous lossis cov khoom me me uas muaj cov khoom me me.

Los ntawm Qhov Loj ntawm Chaw Nres Nkoj:

- Qhov Chaw Puv Tag Nrho (Qhov Qhov Puv): Qhov qhov sib xws nrog txoj kab uas hla ntawm cov yeeb nkab - kev txwv kev ntws tsawg kawg nkaus, tsim nyog rau kev ntxuav cov yeeb nkab (kev ntxuav cov yeeb nkab).

- Qhov Chaw Txo Qhov (Qhov Qhov Txheem): Qhov me dua—pheej yig rau cov ntawv thov uas qhov siab poob qis tau (HVAC, kev plumbing dav dav).

Los ntawm kev ua haujlwm:

- Cov Pob Valves Tes: Kev ua haujlwm ntawm lub log lossis lub log tes—yooj yim, txhim khu kev qha rau kev siv tsis tshua muaj.

- Cov Pob Valves Pneumatic: Kev ua haujlwm cua compressed - teb sai rau kev siv tshuab hauv kev lag luam.

- Cov Pob Hluav Taws Xob: Kev ua haujlwm siv lub cev muaj zog - kev tswj chaw taws teeb rau cov tshuab ntse (PLC, IoT kev koom ua ke).

Los ntawm Txoj Kev Nqus Dej:

- 2-Txoj Kev Pob Valves: Kev tswj hwm rau / tawm rau ib txoj kev ntws - feem ntau yog.

- 3-Txoj Kev Pob Valves: Lub qhov T/L-zoo li tus rau kev sib tov, kev hloov pauv, lossis kev thim rov qab (cov txheej txheem hydraulic, kev ua tshuaj lom neeg).

Cov Khoom Siv Siv Hauv Kev Tsim Kho Lub Pob Valve

Kev xaiv cov khoom siv nyob ntawm cov xov xwm, kub, thiab siab—cov ntaub ntawv tseem ceeb suav nrog:

- Lub cev valve:

- Hlau Tsis Xeb (304/316): Tiv taus xeb, siv tau ntau yam rau kev siv hauv kev lag luam thiab qib zaub mov.

- Tooj Liab: Tus nqi tsim nyog, ua kom muaj cua sov zoo - zoo tagnrho rau cov kav dej hauv tsev thiab HVAC.

- Hlau cam khwb cia: Siv tau ntev, tiv taus siab - siv rau hauv cov kav dej loj hauv kev lag luam.

- Titanium Alloy: Sib dua, tiv taus xeb heev—haum rau hauv dej hiav txwv, tshuaj lom neeg, thiab qhov kub thiab txias (tus nqi zoo tshaj).

- Cov ntsaws ruaj ruaj thiab cov rooj zaum:

- PTFE (Teflon): Tiv taus tshuaj lom neeg, tsis muaj kev sib txhuam—pov mos rau qhov kub thiab txias ib txwm thiab qhov siab tsawg (dej, cua).

- PPL (Polypropylene): Ua tau kub heev (txog li 200 ℃)—zoo dua PTFE rau cov kua kub.

- Hlau (Stellite/Carbide): Kaw ruaj khov rau kev siv siab/kub siab (pas dej, roj).

- Pob thiab qia:

- Hlau Tsis Xeb: Tus qauv rau feem ntau daim ntawv thov - qhov chaw ci ntsa iab ua kom muaj kev sib khi zoo.

- Cov Hlau Alloy: Lub zog txhim kho rau cov tshuab siab.

Kev Txij Nkawm thiab Kev Saib Xyuas Lub Pob Valves

Kev saib xyuas kom zoo yuav ua rau lub pob valve siv tau ntev (txog li 30 xyoo) thiab ua kom ntseeg tau tias muaj kev ntseeg siab:

- Kev Tshuaj Xyuas Tsis Tu Ncua: Xyuas cov foob kom paub seb puas muaj qhov xau, cov kav valve puas muaj xeb, thiab cov khoom siv txuas kom paub tias nruj txhua 3-6 lub hlis.

- Kev Ntxuav: Tshem tawm cov khib nyiab sab hauv thiab cov av sab nraud kom tiv thaiv kev txhaws ntawm lub valve—siv cov tshuaj yaj uas sib xws rau cov xov xwm corrosive.

- Kev Siv Lubrication: Siv cov roj nplua nyeem (sib xws nrog cov foob/cov ntaub ntawv) rau cov kav thiab cov bearings txhua peb lub hlis kom txo tau kev sib txhuam.

- Kev Tiv Thaiv Kev Xeb: Tsuag cov tshuaj tiv thaiv xeb lossis cov quav ciab sab nraud - tseem ceeb rau kev siv sab nraum zoov lossis hauv dej hiav txwv.

- Hloov Cov Khoom Uas Siv Lawm: Hloov cov foob, gaskets, lossis cov khoom ntim uas siv lawm txhua xyoo (lossis raws li cov lus qhia ntawm lub chaw tsim khoom).

- Cov Kev Xyaum Zoo Tshaj Plaws Hauv Kev Ua Haujlwm: Tsis txhob siv cov levers nruj dhau, tsis txhob siv cov extensions (kev pheej hmoo ntawm kev puas tsuaj), thiab sim ua haujlwm kaw thaum muaj xwm txheej ceev txhua xyoo.

Piv Txwv Pob Valves Rau Lwm Hom Valve

Kev xaiv lub valve zoo nyob ntawm seb ua haujlwm li cas - ntawm no yog li cas lub pob valve sib dhos ua ke:

| Hom Valve | Qhov Txawv Tseem Ceeb | Zoo Tshaj Plaws Rau |

|---|---|---|

| Pob Valves | Tig ib feem plaub, kaw ruaj khov, tsis tshua muaj dej ntws | Kaw sai, cov xov xwm corrosive, kev tswj hwm qhov tseeb |

| Rooj vag Valves | Kev txav mus los ncaj (rooj vag nce / nqis), kev tiv thaiv dej tsawg kawg nkaus thaum qhib | Siv tau ntev (faib dej) |

| Npauj Npaim Valves | Sib dua, me me, pheej yig dua | Cov kab ke loj, cov tshuab siab qis (dej khib nyiab) |

| Cov Li Qub Ntiaj Teb | Kev txav mus los ncaj, kev tswj hwm zoo dua | Cov txheej txheem ua pa, kev hloov kho zaus |

| Cov Qhov Txuas | Zoo ib yam li lub pob valve tab sis lub cylindrical plug | Cov khoom siv kub thiab viscosity siab |

Cov pob li qub ua tau zoo dua lwm tus hauv kev ntseeg tau ntawm kev sib khi, kev ceev, thiab kev hloov pauv tau yooj yim - ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau feem ntau ntawm kev lag luam thiab kev lag luam.

Cov Qauv Kev Lag Luam thiab Cov Ntawv Pov Thawj rau Pob Valves

Kev ua raws li cov qauv thoob ntiaj teb ua kom muaj kev zoo, kev nyab xeeb, thiab kev sib koom tes:

- API (American Petroleum Institute): API 6D rau cov kav dej kav dej, API 608 rau cov kav dej ntab - tseem ceeb rau roj thiab roj av.

- ANSI (Lub Koom Haum Txuj Ci Txuj Ci Hauv Tebchaws Asmeskas): ANSI B16.34 rau qhov ntev ntawm lub valve thiab qhov ntsuas siab—ua kom muaj kev sib raug zoo nrog cov kav dej hauv Tebchaws Meskas.

- ISO (Lub Koom Haum Thoob Ntiaj Teb rau Kev Txheem): ISO 9001 (kev tswj hwm zoo), ISO 15848 (kev tswj cov pa phem) - kev lees paub thoob ntiaj teb.

- AWWA (American Water Works Association): AWWA C507 rau cov qhov dej thiab cov kav dej khib nyiab—ua kom muaj kev nyab xeeb ntawm cov dej haus.

- EN (European Norm): EN 13480 rau cov li qub lag luam - kev ua raws li cov lag luam European.

- Cov ntawv pov thawj xws li CE (European Conformity) thiab FM (Fire Protection) qhia txog kev ua raws li cov qauv kev nyab xeeb thiab ib puag ncig.

Xaus Lus thiab Yav Tom Ntej Cov Qauv Hauv Kev Siv Tshuab Pob Valve

Cov pob valve tau hloov zuj zus los ntawm cov khoom siv yooj yim mus rau cov cuab yeej tseem ceeb hauv kev tswj cov kua niaj hnub, tsav kev ua haujlwm zoo thoob plaws hauv kev lag luam. Lawv qhov kev sib xyaw ua ke ntawm kev ceev, kev sib khi, thiab kev ruaj khov ua rau lawv yog qhov kev xaiv zoo rau cov ntawv thov xws li cov kav dej hauv tsev mus rau kev tshawb nrhiav roj hauv hiav txwv tob.

Yav tom ntej ntawm lub pob valve thev naus laus zis yog tsim los ntawm peb qhov tseem ceeb:

- Kev Sib Koom Tes Ntse: Cov twj tso kua mis uas siv IoT nrog cov sensors rau qhov siab, kub, thiab qhov chaw ntawm lub twj tso kua mis—ua rau muaj kev saib xyuas tiag tiag thiab kev saib xyuas ua ntej (txo lub sijhawm tsis ua haujlwm los ntawm 30%+).

- Kev Tsim Kho Tshiab ntawm Cov Khoom Siv: Cov hlau sib xyaw thiab cov khoom sib xyaw ua ke (piv txwv li, cov txheej txheem ceramic, carbon fiber) rau cov xwm txheej hnyav (siab/kub siab dua, tiv taus xeb zoo dua).

- Kev Siv Hluav Taws Xob Zoo: Cov qauv tsim uas tsis hnyav thiab cov khoom sib txhuam tsawg los txo kev siv hluav taws xob - ua raws li lub hom phiaj thoob ntiaj teb kev ruaj khov.

- Cov Ntawv Thov Uas Nthuav Dav: Kev loj hlob ntawm lub zog rov ua dua tshiab (kev tswj cov kua dej los ntawm lub zog hnub ci/cua) thiab biotech (kev tsim tshuaj kho mob kom raug) yuav tsav kev xav tau cov pob valve tshwj xeeb.

Nrog rau kev lag luam thoob ntiaj teb kwv yees tias yuav ncav cuag $ 19.6 billion los ntawm xyoo 2033, lub pob valve yuav tseem nyob rau pem hauv ntej ntawm kev lag luam automation thiab kev tswj hwm kua dej tshiab.

Xav tau kev pab xaiv lub pob valve uas haum rau koj daim ntawv thov? Kuv tuaj yeem tsim daim ntawv teev npe xaiv lub pob valve uas haum rau koj txoj kev lag luam, hom xov xwm, thiab qhov yuav tsum tau ua kom siab/kub - qhia rau kuv paub yog tias koj xav pib!

Lub sijhawm tshaj tawm: Kaum Ib Hlis-10-2025