Asetshenziselwani Amavalvu Ebhola?

Amavalvu ebhola ayizingxenye ezibalulekile ezinhlelweni zokulawula uketshezi, aziwa ngokuthembeka kwawo, ukuguquguquka kwawo, kanye nokusebenza kahle kuzo zonke izimboni. Kusukela kumapayipi ezindlu kuya kuma-rig kawoyela olwandle olujulile, lawa mavalvu ajika ngekota adlala indima ebalulekile ekulawuleni ukugeleza koketshezi, amagesi, ngisho nemidiya eqinile. Kulesi siqondisi esiphelele, sizohlola ukuthi amavalvu ebhola asebenza kanjani, izinzuzo zawo ezibalulekile, ukusetshenziswa okuvamile, kanye nezitayela zesikhathi esizayo—ukukuhlomisa ngolwazi lokukhetha nokusebenzisa kahle.

Indlela Ama-Ball Valve Asebenza Ngayo

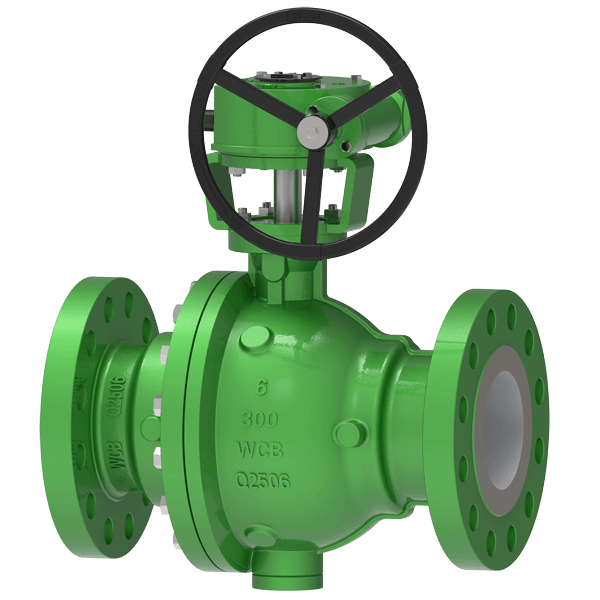

Embindini wawo, amavalvu ebhola asebenza ngendlela elula kodwa ephumelelayo: idiski eliyindilinga elijikelezayo ("ibhola") elinembobo ephakathi (umgodi) lilawula ukugeleza koketshezi. Ukusebenza kwevalvu kuncike ezingxenyeni ezintathu ezibalulekile: umzimba wevalvu (ogcina izingxenye zangaphakathi futhi oxhumanisa namapayipi), ibhola elinezimbobo (umbindi olawula ukuvulwa nokuvalwa), kanye nesiqu (esidlulisela amandla okujikeleza kusuka ku-actuator kuya ebholeni).

Uma imbobo yebhola ihambisana nepayipi, ivalvu ivuleka ngokuphelele, okuvumela ukugeleza okungaphazanyiswa. Ukujikeleza ibhola ngama-degree angu-90 (ukujika kwekota) kubeka ingxenye eqinile yebhola endleleni yokugeleza, kuvale ukugeleza ngokuphelele. Ukusebenza kungaba ngesandla (nge-lever noma i-handwheel) noma okuzenzakalelayo (i-pneumatic, kagesi, noma i-hydraulic) yokulawula okude noma okunembile. Imiklamo emibili evamile ithuthukisa ukuguquguquka: amavalvu ebhola antantayo (lapho ibhola lishintsha kancane ngaphansi kwengcindezi ukuze livalwe) kanye namavalvu ebhola afakwe ku-trunnion (lapho ibhola liboshwe yiziqu eziphezulu nezingezansi ukuze kusetshenziswe ngokucindezela okuphezulu).

Izinzuzo Eziyinhloko Zokusebenzisa Ama-Ball Valve

Ama-valve ebhola ahlukile phakathi kwezixazululo zokulawula uketshezi ngenxa yokusebenza kwawo okuqinile kanye nezinzuzo ezigxile kumsebenzisi:

- Ukuvula Nokuvala Okusheshayo: Ukujikeleza kwamadigri angu-90 kuqeda imijikelezo yokuvula/yokuvala egcwele ngemizuzwana engu-0.5 nje kuphela, okwenza kube kuhle kakhulu ezimweni eziphuthumayo zokuvala njengezinhlelo zomlilo noma ukuvuza kwegesi.

- Ukuvala Okuphezulu: Amamodeli e-Soft-seal (PTFE) afinyelela ukuvala okungenamagwebu (ukuvuza okungu-≤0.01% KV), kuyilapho izinhlobo ze-hard-seal (zensimbi) zigcina ukuthembeka ezimweni zokucindezela okuphezulu/zokushisa okuphezulu—okubalulekile ezintweni ezivuthayo neziqhumayo noma ezibhubhisayo.

- Ukumelana Nokugeleza Okuphansi: Amavalvu ebhola agcwele imbobo anesimbobo esilingana nobubanzi bepayipi, okuholela ekwehleni okuncane kwengcindezi (i-coefficient yokumelana engu-0.08-0.12) kanye nokonga amandla kwezinhlelo ezinkulu.

- Ukuqina Nokuguquguquka: Imelana namazinga okushisa asukela ku--196℃ (LNG) kuya ku-650℃ (izitofu zezimboni) kanye nokucindezela okufika ku-42MPa, ivumelane noketshezi, amagesi, kanye nemidiya egcwele izinhlayiya njenge-slurry.

- Ukulungiswa Okulula: Imiklamo ye-Modular ivumela ukulungiswa okusemugqeni (akukho ukuhlukaniswa kwamapayipi) kanye nezivalo ezingashintshwa, okunciphisa isikhathi sokulungisa ngo-50% uma kuqhathaniswa nama-valve esango.

Ukusetshenziswa Okuvamile Kwama-Ball Valve

Ama-valve ebhola atholakala kuyo yonke imboni, ngenxa yokuzivumelanisa nezimo zokusebenza ezahlukahlukene:

- Uwoyela negesi: Kusetshenziswa emipayipini kawoyela ongahluziwe, ukusatshalaliswa kwegesi yemvelo, kanye nama-terminal e-LNG—ama-valve ebhola aqinile aphatha ukudluliselwa komfutho ophezulu, kuyilapho amamodeli ahlanganisiwe efanela ukufakwa ngaphansi komhlaba.

- Amakhemikhali kanye Nezemithi: Amavalvu ebhola ahlanganiswe nge-PTFE noma i-titanium alloy alawula ama-asidi, izinyibilikisi, kanye noketshezi oluhlanzekile, ahlangabezana nezindinganiso zokuhlanzeka zokukhiqiza imithi.

- Amanzi Namanzi Angcolile: Amavalvu ebhola antantayo alawula ukusatshalaliswa kwamanzi kamasipala kanye nokwelashwa kwendle, ngemiklamo ye-V-port ephatha ukungcola okugcwele okuqinile ngesenzo sokucheba.

- Amandla Namandla: Lawula amanzi okuhambisa amanzi kubhoyila, ukugeleza komusi, kanye nezinhlelo zokupholisa ezitshalweni zamandla ezishisayo nezenuzi—ama-alloy okushisa okuphezulu amelana nokushisa okukhulu.

- Ukudla Neziphuzo: Amavalvu ebhola lokuhlanzeka anengaphakathi elibushelelezi nelingenamifantu avimbela ukungcola ekucutshungulweni kwejusi, ekukhiqizweni kobisi, nasekuphekeni.

- Izindlu Nezebhizinisi: Ama-valve ebhola asetshenziswa ngesandla avala imigqa yegesi, izinhlelo ze-HVAC, kanye namapayipi, kuyilapho amamodeli kagesi enza ngokuzenzakalelayo ukulawula izinga lokushisa ezakhiweni ezihlakaniphile.

- Izimboni Ezikhethekile: Izindiza (izinhlelo zikaphethiloli), ezasolwandle (amapulatifomu asogwini), kanye nezezimayini (ukuthutha okusaluketshezi) zithembele emiklamo eqinile yezindawo ezinzima.

Izinhlobo Ezihlukene Zama-Ball Valve

Ama-valve ebhola ahlukaniswa ngomklamo, usayizi we-port, kanye nokusebenza, ngalinye lenzelwe izidingo ezithile:

Ngomklamo Webhola:

- Amavalvu Ebhola Elintantayo: Ibhola “liyantanta” ukuze livalwe esihlalweni—lilula, lingabizi kakhulu uma licindezelwa kancane kuya phakathi (amapayipi e-DN≤50).

- Amavalvu Ebhola Afakwe I-Trunnion: Ibhola eliqiniswe yi-trunnion—i-torque ephansi, ilungele ukusetshenziswa komfutho ophezulu (kufika ku-PN100) kanye nobubanzi obukhulu (DN500+).

- Ama-V-Port Ball Valve: Imbobo enomumo we-V yokugoqa okunembile (isilinganiso esilungisekayo esingu-100:1) kanye nesenzo sokusika—ilungele imidiya egobile noma egcwele izinhlayiya.

Ngosayizi Wechweba:

- Imbobo Egcwele (Imbobo Egcwele): Imbobo ihambisana nobubanzi bepayipi—umkhawulo omncane wokugeleza, ofanelekela ukuhlanzwa kwepayipi.

- Imbobo Encishisiwe (Imbobo Ejwayelekile): Imbobo encane—engabizi kakhulu lapho kusetshenziswa khona ukwehla komfutho (i-HVAC, amapayipi ajwayelekile).

Ngokwesenzo:

- Amavalvu Ebhola Enziwe Ngesandla: Ukusebenza kwe-lever noma i-handwheel—kulula, kuthembekile ukusetshenziswa njalo.

- Amavalvu Ebhola Lomoya: Ukusebenza komoya okucindezelwe—impendulo esheshayo yokwenza izinto ngokuzenzakalela kwezimboni.

- Amavalvu Ebhola Likagesi: Ukusebenza kwenjini—ukulawula kude kwezinhlelo ezihlakaniphile (i-PLC, ukuhlanganiswa kwe-IoT).

Ngendlela Yokugeleza:

- Amavalvu Ebhola Anezindlela Ezimbili: Ukulawula ukuvala/ukuvula kwezindlela zokugeleza okukodwa—okuvame kakhulu.

- Amavalvu Ebhola Anezindlela Ezi-3: Imbobo enomumo we-T/L yokuxuba, ukuphambukisa, noma ukubuyisela emuva ukugeleza (izinhlelo ze-hydraulic, ukucubungula amakhemikhali).

Izinto Ezisetshenziswa Ekwakhiweni Kwe-Ball Valve

Ukukhethwa kwezinto kuncike kumidiya, izinga lokushisa, kanye nengcindezi—izinto ezibalulekile zifaka:

- Umzimba weValve:

- Insimbi Engagqwali (304/316): Ayigqwali, isebenziseka kalula ezinhlotsheni zezimboni kanye nezinga lokudla.

- Ithusi: Isebenza kahle ekushiseni, ilungele amapayipi asekhaya kanye ne-HVAC.

- Insimbi Ebunjiwe: Ihlala isikhathi eside, imelana nokucindezela okuphezulu—esetshenziswa emapayipini amakhulu ezimboni.

- I-Titanium Alloy: Ilula, imelana nokugqwala okukhulu—ifanele izindawo zasolwandle, zamakhemikhali, kanye nezimo zokushisa okuphezulu (intengo-i-premium).

- Izimpawu Nezihlalo:

- I-PTFE (i-Teflon): Ayimelani namakhemikhali, ayishayisani kahle—ivala kalula izinga lokushisa elijwayelekile kanye nemidiya ecindezelekile ephansi (amanzi, umoya).

- I-PPL (i-Polypropylene): Ukubekezelela izinga lokushisa eliphezulu (kufika ku-200℃)—kungcono kune-PTFE yoketshezi olushisayo.

- Insimbi (i-Stellite/i-Carbide): I-Hard-seal yokusetshenziswa kokucindezela okuphezulu/ukushisa okuphezulu (umusi, uwoyela).

- Ibhola kanye nesiqu:

- Insimbi Engagqwali: Okujwayelekile kwezicelo eziningi—indawo epholishiwe iqinisekisa ukuvalwa okuqinile.

- Insimbi Ehlanganisiwe: Amandla athuthukisiwe ezinhlelo ezinomfutho ophezulu.

Ukunakekelwa Nokunakekelwa Kwama-Ball Valve

Ukugcinwa kahle kwandisa isikhathi sokuphila kwevalvu yebhola (kuze kube yiminyaka engama-30) futhi kuqinisekisa ukuthembeka:

- Ukuhlolwa Okuvamile: Hlola izivalo ukuze zingavuzi, iziqu zamavalvu ukuze zingagqwali, kanye nezinamathiseli ukuze ziqine njalo ezinyangeni ezi-3-6.

- Ukuhlanza: Susa imfucuza yangaphakathi kanye nokungcola kwangaphandle ukuze uvimbele ukuminyana kwama-valve—sebenzisa izinyibilikisi ezihambisanayo zemidiya ebolile.

- Ukugcotshwa: Faka amafutha okugcoba (ahambisana nezivalo/izinto zokwakha) eziqwini nasemabhereni njalo ngekota ukuze unciphise ukungqubuzana.

- Ukuvikelwa Kokugqwala: Futha izinto ezilwa nokugqwala noma izindawo zangaphandle ze-wax—ezibalulekile ekusetshenzisweni kwangaphandle noma olwandle.

- Shintsha Izingxenye Zokugqoka: Shintsha izivalo ezigugile, ama-gasket, noma ukupakisha minyaka yonke (noma ngokweziqondiso zomkhiqizi).

- Izindlela Ezinhle Zokusebenza: Gwema ama-lever aqinisa kakhulu, ungalokothi usebenzise izandiso (ingozi yokulimala), futhi uhlole ukusebenza kokuvala okuphuthumayo minyaka yonke.

Ukuqhathanisa Amavalvu Ebhola Nezinye Izinhlobo Zamavalvu

Ukukhetha ivalvu efanele kuncike ezimweni zokusebenza—nansi indlela amavalvu ebhola ahlangana ngayo:

| Uhlobo lwe-Valve | Umehluko Oyinhloko | Okuhle Kakhulu Kwaba |

|---|---|---|

| Amavalvu Ebhola | Ukujika kwekota, ukuvala okuqinile, ukumelana nokugeleza okuphansi | Ukuvala okusheshayo, imidiya egqwalisayo, ukulawula okunembile |

| Amavalvu Esango | Ukunyakaza okuqondile (isango phezulu/phansi), ukumelana okuncane kokugeleza uma livuliwe | Ukusetshenziswa okuvulekile isikhathi eside (ukusatshalaliswa kwamanzi) |

| Amavalvu Ovemvane | Ilula, incane, futhi ibiza kancane | Izinhlelo ezinkulu ezinobukhulu obuphansi (amanzi angcolile) |

| Amavalvu Embulunga | Ukunyakaza okuqondile, ukugoba okuphezulu | Izinhlelo zomusi, ukulungiswa kokugeleza okuvamile |

| Amavalvu e-plug | Kufana nama-valve ebhola kodwa ipulaki eliyindilinga | Imidiya yokushisa okuphezulu, ene-viscosity ephezulu |

Amavalvu ebhola adlula amanye ngokuthembeka kokuvala, isivinini, kanye nokuguquguquka—okuwenza abe ukukhetha okuphezulu kwezicelo eziningi zezimboni nezentengiselwano.

Izindinganiso Zemboni kanye Nezitifiketi Zama-Ball Valve

Ukuhambisana nezindinganiso zomhlaba wonke kuqinisekisa ikhwalithi, ukuphepha, kanye nokusebenzisana kahle:

- I-API (i-American Petroleum Institute): I-API 6D yama-valve epayipi, i-API 608 yama-valve ebhola antantayo—ibalulekile ku-oyili negesi.

- I-ANSI (i-American National Standards Institute): I-ANSI B16.34 yobukhulu bamavalvu kanye nezilinganiso zokucindezela—iqinisekisa ukuhambisana namapayipi ase-US.

- I-ISO (Inhlangano Yomhlaba Wonke Yokumisa): I-ISO 9001 (ukuphathwa kwekhwalithi), i-ISO 15848 (ukulawulwa kokukhishwa kwegesi)—ukwamukelwa emhlabeni jikelele.

- I-AWWA (i-American Water Works Association): I-AWWA C507 yamanzi namavalvu amanzi angcolile—iqinisekisa ukuphepha kwamanzi ahlanzekile.

- EN (European Norm): EN 13480 yamavalvu ezimboni—ukuthobela imithetho yezimakethe zaseYurophu.

- Izitifiketi ezifana ne-CE (European Conformity) kanye ne-FM (Fire Protection) zibonisa ukunamathela ezindinganisweni zokuphepha kanye nezemvelo.

Isiphetho kanye Nezindlela Zesikhathi Esizayo Kubuchwepheshe Be-Ball Valve

Ama-ball valve ashintshe kusukela ezingxenyeni ezilula zemishini kuya kumathuluzi abalulekile ekulawuleni uketshezi lwesimanje, okuqhuba ukusebenza kahle kuzo zonke izimboni. Inhlanganisela yawo eyingqayizivele yesivinini, ukuvala, kanye nokuqina iwenza abe yinketho ethandwayo yezinhlelo zokusebenza kusukela ekufakweni kwamapayipi emakhaya kuya ekuhlolweni kukawoyela olwandle olujulile.

Ikusasa lobuchwepheshe be-ball valve lakhiwe yizindlela ezintathu ezibalulekile:

- Ukuhlanganiswa Okuhlakaniphile: Amavalvu asebenzisa i-IoT anezinzwa zokucindezela, izinga lokushisa, kanye nendawo yamavalvu—okuvumela ukuqapha kwesikhathi sangempela kanye nokugcinwa kokubikezela (ukunciphisa isikhathi sokungasebenzi ngo-30% nangaphezulu).

- Ukuqamba Izinto: Ama-alloy athuthukisiwe kanye nezinhlanganisela (isb., izembozo ze-ceramic, i-carbon fiber) ezimweni ezimbi kakhulu (ukucindezela/ukushisa okuphezulu, ukumelana nokugqwala okunamandla).

- Ukusetshenziswa Kahle Kwamandla: Imiklamo elula kanye nezingxenye eziphansi zokungqubuzana ukuze kuncishiswe ukusetshenziswa kwamandla—okuhambisana nemigomo yokuzinza komhlaba wonke.

- Izicelo Ezandisiwe: Ukukhula kwamandla avuselelekayo (ukulawulwa koketshezi lwamandla elanga/omoya) kanye ne-biotech (ukukhiqizwa kwemithi okunembile) kuzothuthukisa isidingo sama-ball valve akhethekile.

Njengoba imakethe yomhlaba wonke kulindeleke ukuthi ifinyelele ku-$19.6 billion ngo-2033, ama-ball valve azohlala ehamba phambili ekusetshenzisweni kwezimboni kanye nokusungula izinto ezintsha zokulawula uketshezi.

Udinga usizo lokukhetha ivalvu yebhola efanele isicelo sakho? Ngingakha uhlu lokuhlola lokukhetha ivalvu yebhola elenziwe ngokwezifiso oluhambisana nomkhakha wakho, uhlobo lwemidiya, kanye nezidingo zokucindezela/izinga lokushisa—ngitshele uma ungathanda ukuqala!

Isikhathi sokuthunyelwe: Novemba-10-2025