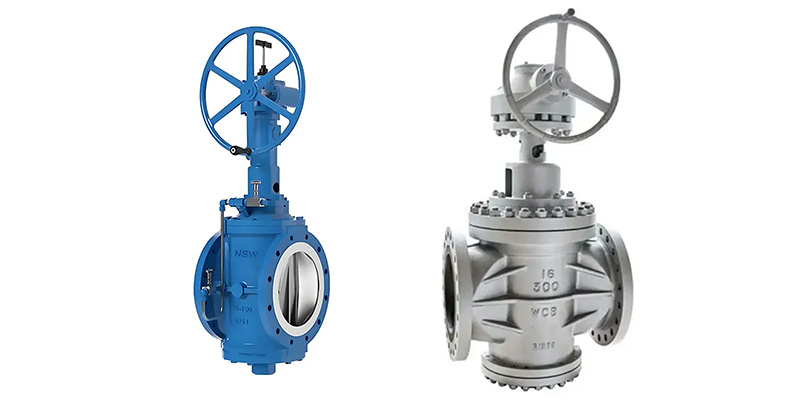

Plug valves are fundamental components in industrial fluid handling, prized for their straightforward design, durability, and effective shutoff capabilities. These valves operate by rotating a cylindrical or conical plug inside the valve body to open or block fluid flow. Their quarter-turn operation and minimal internal flow resistance make them ideal for applications requiring rapid response and high efficiency, such as oil and gas pipelines, chemical processing plants, and HVAC systems.

Recent advancements in plug valve design focus on enhancing sealing reliability and operational longevity. A standout feature in modern designs is the Double Block and Bleed (DBB) configuration. This setup employs two independent sealing surfaces that provide a verified bubble-tight seal, ensuring complete fluid isolation. Such dual sealing is critical for maintenance and safety in high-pressure environments, allowing for system bleed-off and testing without interrupting overall operations.

Key characteristics of modern plug valves include:

✅Simple and Efficient Operation

The quarter-turn mechanism enables quick valve actuation with low operating torque, reducing wear and easing automation.

✅Minimal Pressure Loss

The streamlined flow path inside plug valves ensures low turbulence and pressure drop, optimizing system energy efficiency.

✅Enhanced Sealing Technology

Combining hard metal-to-metal seats with elastomeric seals like fluorine or nitrile rubber, modern valves achieve both durability and tight leak prevention under varied conditions.

✅Wear Resistance and Longevity

Hard chrome plating and other surface treatments protect internal valve components from abrasion and corrosion, extending service intervals.

✅Maintenance-Friendly Design

Innovative modular components, such as independently mounted sealing slips, allow quick in-place maintenance without removing the valve from pipelines, minimizing downtime and operational costs.

✅Dual Block and Bleed Functionality

Independent sealing elements enable safe venting and leak detection, increasing operational safety in critical systems.

✅Wide Industrial Applicability

Suitable for harsh environments including oil & gas, petrochemical, power generation, and HVAC sectors, these valves handle high temperature and pressure with stability.

✅Compact Footprint

The compact, robust construction of plug valves facilitates installation in tight spaces, supporting modern, space-conscious plant designs.

The continued innovation in plug valve engineering not only improves operational reliability and safety but also reduces total cost of ownership through easier maintenance and longer life cycles. As industries face growing demands for efficiency, safety, and environmental compliance, advanced plug valves stand out as essential elements in fluid control systems worldwide.

Post time: Aug-08-2025