In industrial automation systems, the Pneumatic Actuator Valve is an essential component for fluid control, offering efficiency, reliability, and safety across sectors like oil and gas, chemical processing, power generation, and water treatment. This detailed guide breaks down the fundamentals of Pneumatic Actuator Valves, helping professionals and purchasers grasp critical information quickly.

What Are Pneumatic Actuator Valves

Pneumatic Actuator Valves, often simply called pneumatic valves, are automated fluid regulation devices powered by compressed air. They use a pneumatic actuator to open, close, or modulate valve operation, enabling precise control over flow, pressure, and temperature of gases, liquids, and steam in pipelines. Compared to traditional valves, a Pneumatic Actuator Valve provides faster response times, effortless operation, and remote control capabilities, making them ideal for harsh environments, high-frequency use, and automated systems requiring minimal human intervention.

How Pneumatic Actuator Valves Work

Pneumatic Actuator Valves operate on the principle of “air pressure driving mechanical action.” The process involves three key steps:

- Signal Reception: A control system (e.g., PLC or DCS) sends a pneumatic signal (typically 0.2–1.0 MPa) through air lines to the actuator.

- Power Conversion: The actuator’s piston or diaphragm converts compressed air energy into mechanical force.

- Valve Operation: This force drives the valve core (e.g., ball, disc, or gate) to rotate or move linearly, adjusting the flow or shutting off the medium.

Many Pneumatic Actuator Valves include spring-return mechanisms that automatically reset the valve to a safe position (fully open or closed) during air supply failure, enhancing system safety.

Main Components of Pneumatic Actuator Valves

Pneumatic Actuator Valves consist of three core components that work together to ensure efficient fluid control.

Pneumatic Actuator

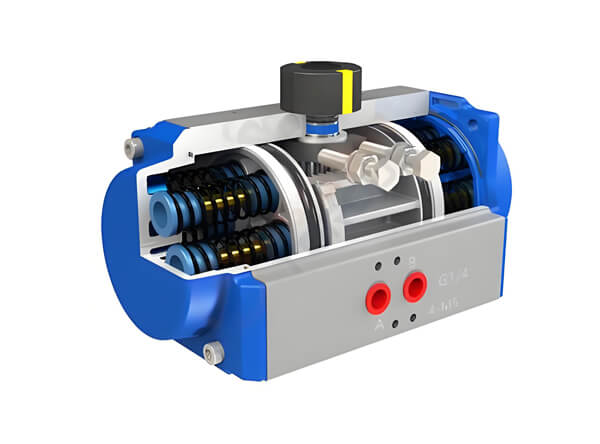

The actuator is the power source of the Pneumatic Actuator Valve, transforming air pressure into mechanical motion. Common types include:

- Piston Actuators: Use a cylinder-piston design for high torque output, suitable for large-diameter and high-pressure applications. Available in double-acting (air-driven in both directions) or single-acting (spring-return) models.

- Diaphragm Actuators: Feature a rubber diaphragm for simple construction and corrosion resistance, ideal for low-to-medium pressure and small-sized valves.

- Scotch and Yoke: A pneumatic actuators deliver precise 90-degree rotation, making them an ideal drive solution for quick on/off or regulated metering control in ball, butterfly, and plug valves.

- Rack and Pinion: It driven by dual pistons, these pneumatic actuators are offered in both double-acting and single-acting (spring-return) configurations. They provide reliable force for operating linear and rotary control valves.

Key parameters include output torque, operating speed, and pressure range, which must match valve specifications and operational needs.

Valve Body

The valve directly interfaces with the medium and regulates its flow. Critical parts include:

- Valve Body: The main housing that withstands pressure and contains the medium; materials (e.g., carbon steel, stainless steel) are selected based on fluid properties.

- Valve Core and Seat: These components work together to adjust flow by changing the gap between them, requiring high precision, wear resistance, and corrosion tolerance.

- Stem: Connects the actuator to the valve core, transmitting force while maintaining rigidity and leak-tight seals.

Pneumatic Accessories

Accessories enhance control accuracy and operational stability for Pneumatic Actuator Valves:

- Positioner: Converts electrical signals (e.g., 4–20 mA) into precise air pressure signals for accurate valve positioning.

- Filter Regulator: Removes impurities and moisture from compressed air while stabilizing pressure.

- Solenoid Valve: Enables remote on/off control via electrical signals.

- Limit Switch: Provides feedback on valve position for system monitoring.

- Air Amplifier: Boosts air signals to accelerate actuator response in large valves.

Classification of Pneumatic Actuator Valves

Pneumatic Actuator Valves are categorized by design, function, and application:

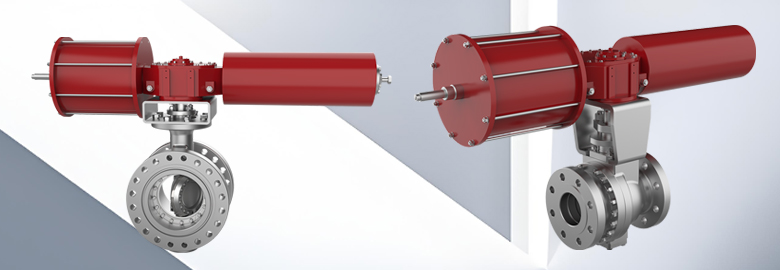

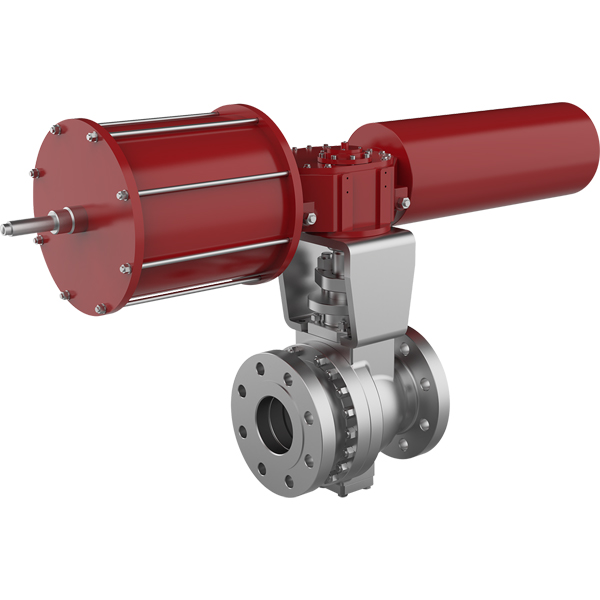

Pneumatic Actuator Ball Valves

Use a rotating ball to control flow. Benefits: Excellent sealing (zero leakage), low flow resistance, quick operation, and compact size. Types include floating and fixed ball designs, widely used in petroleum, chemical, and water treatment industries.

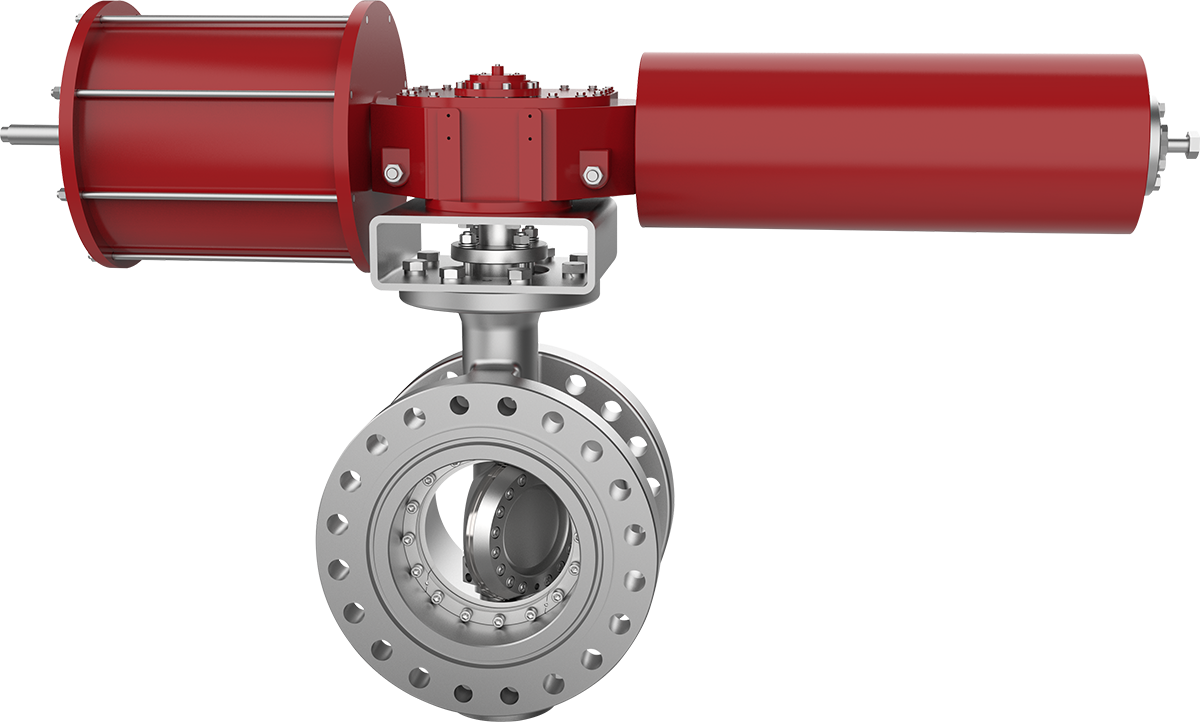

Pneumatic Actuator Butterfly Valves

Feature a disc that rotates to regulate flow. Advantages: Simple structure, lightweight, cost-effective, and suitable for large diameters. Common in water systems, ventilation, and HVAC applications. Sealing options include soft seals (rubber) for low pressure and hard seals (metal) for high temperatures.

Pneumatic Actuator Gate Valves

Employ a gate that moves vertically to open or close. Pros: Tight sealing, minimal flow resistance when fully open, and high pressure/temperature tolerance. Ideal for steam pipelines and crude oil transport but slower in operation.

Pneumatic Actuator Globe Valves

Utilize a plug or needle-style core for precise flow adjustment. Strengths: Accurate control, reliable sealing, and versatility for high-pressure/viscous media. Common in chemical and hydraulic systems, though they have higher flow resistance.

Shut Down Valves (SDV)

Designed for emergency isolation, often fail-safe closed. They activate rapidly (response ≤1 second) upon signal, ensuring safety in hazardous media handling (e.g., natural gas stations, chemical reactors).

Advantages of Pneumatic Actuator Valves

Key benefits driving their industrial adoption:

- Efficiency: Fast response (0.5–5 seconds) supports high-frequency operations.

- Safety: No electrical risks, making them suitable for explosive or corrosive environments; spring-return adds fail-safe protection.

- Ease of Use: Remote and automated control reduces manual labor.

- Durability: Simple mechanical parts result in low wear, minimal maintenance, and long service life (8–10 years average).

- Adaptability: Customizable materials and accessories handle diverse conditions like high temperature, corrosion, or particulate-laden media.

Pneumatic Actuator Valves vs. Electric Valves

| Aspect | Pneumatic Actuator Valves | Electric Actuator Valves |

|---|---|---|

| Power Source | Compressed air | Electricity |

| Response Speed | Fast (0.5–5 seconds) | Slower (5–30 seconds) |

| Explosion Proofing | Excellent (no electrical parts) | Requires special design |

| Maintenance Cost | Low (simple mechanics) | Higher (motor/gearbox wear) |

| Control Precision | Moderate (needs positioner) | High (built-in servo) |

| Ideal Applications | Hazardous, high-cycle environments | Precision control, no air supply |

Pneumatic Actuator Valves vs. Manual Valves

| Aspect | Pneumatic Actuator Valves | Manual Valves |

|---|---|---|

| Operation | Automated/remote | Hand-operated |

| Labor Intensity | Low | High (large valves need effort) |

| Response Speed | Fast | Slow |

| Automation Integration | Compatible with PLC/DCS | Not integrable |

| Typical Use Cases | Automated lines, unmanned systems | Small setups, backup duty |

Main Applications of Pneumatic Actuator Valves

Pneumatic Actuator Valves are versatile across industries:

- Oil & Gas: Crude extraction, refining, and chemical reactors for high-pressure/temperature fluids.

- Power Generation: Steam and cooling water control in thermal/nuclear plants.

- Water Treatment: Flow regulation in water supply and wastewater plants.

- Natural Gas: Pipeline and station safety shut-off.

- Food & Pharma: Sanitary-grade valves (e.g., 316L stainless steel) for sterile processing.

- Metallurgy: Cooling/hydraulic systems in high-temperature, dusty mills.

Installation and Maintenance of Pneumatic Actuator Valves

Proper setup and care ensure long-term performance of your Pneumatic Actuator Valves.

Installation Guidelines

- Selection: Match valve type, size, and material to media properties (e.g., temperature, pressure) to avoid under- or over-sizing.

- Environment: Install away from direct sunlight, heat, or vibration; mount actuators vertically for easy drainage.

- Piping: Align valve with flow direction (see body arrow); clean sealing surfaces and tighten bolts evenly on flanged connections.

- Air Supply: Use filtered, dry air with dedicated lines; maintain stable pressure within actuator ratings.

- Electrical Connections: Wire positioners/solenoids correctly with grounded shielding to prevent interference; test valve operation after installation.

Maintenance and Care

- Cleaning: Wipe valve surfaces monthly to remove dust, oil, and residue; focus on sealing areas.

- Lubrication: Lubricate stems and actuator parts every 3–6 months with suitable oil (e.g., high-temperature grade).

- Seal Inspection: Check valve seats and cores periodically for leaks; replace seals (O-rings) as needed.

- Accessory upkeep: Inspect positioners, solenoid valves, and filters every 6–12 months; clean filter elements and recalibrate positioners.

- Troubleshooting: Address common issues like sticking (clean debris), slow action (check air pressure), or leaks (tighten bolts/replace seals) promptly.

- Storage: Seal unused valve ports, depressurize actuators, and store in dry areas; rotate valve cores occasionally to prevent seal adhesion.

Post time: Nov-25-2025