What Are Ball Valves Used For?

Ball valves are indispensable components in fluid control systems, renowned for their reliability, versatility, and efficiency across industries. From residential plumbing to deep-sea oil rigs, these quarter-turn valves play a critical role in regulating the flow of liquids, gases, and even solid-laden media. In this comprehensive guide, we’ll dive into how ball valves work, their key benefits, common applications, and future trends—equipping you with the knowledge to choose and use them effectively.

How Ball Valves Work

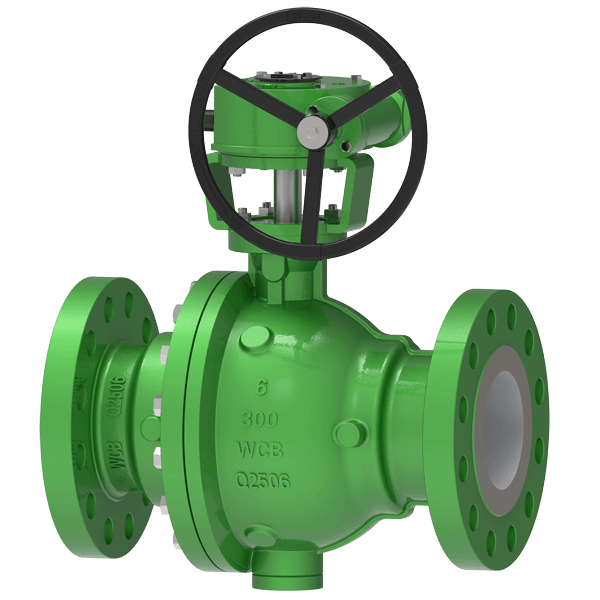

At their core, ball valves operate on a simple yet effective mechanism: a rotating spherical disc (the “ball”) with a central bore (hole) controls fluid flow. The valve’s functionality hinges on three key components: the valve body (which houses internal parts and connects to pipelines), the perforated ball (the core that controls opening and closing), and the stem (which transmits rotational force from the actuator to the ball).

When the ball’s bore aligns with the pipeline, the valve is fully open, allowing unobstructed flow. Rotating the ball 90 degrees (a quarter turn) positions the solid part of the ball across the flow path, shutting off flow completely. Actuation can be manual (via a lever or handwheel) or automated (pneumatic, electric, or hydraulic) for remote or precision control. Two common designs enhance versatility: floating ball valves (where the ball shifts slightly under pressure to seal) and trunnion-mounted ball valves (where the ball is anchored by upper and lower stems for high-pressure use).

Key Benefits of Using Ball Valves

Ball valves stand out among fluid control solutions for their robust performance and user-centric advantages:

- Rapid Opening and Closing: A 90-degree rotation completes full open/close cycles in as little as 0.5 seconds, making them ideal for emergency shutoff scenarios like fire systems or gas leaks.

- Superior Sealing: Soft-seal (PTFE) models achieve bubble-tight sealing (leakage ≤0.01% KV), while hard-seal (metal) versions maintain reliability in high-pressure/high-temperature conditions—critical for flammable and explosive or corrosive media.

- Low Flow Resistance: Full-port ball valves feature a bore equal to the pipeline diameter, resulting in minimal pressure drop (resistance coefficient 0.08-0.12) and energy savings for large-volume systems.

- Durability and Versatility: Withstand temperatures from -196℃ (LNG) to 650℃ (industrial furnaces) and pressures up to 42MPa, adapting to liquids, gases, and particle-laden media like slurry.

- Easy Maintenance: Modular designs allow in-line repairs (no pipe disassembly) and replaceable seals, cutting maintenance time by 50% compared to gate valves.

Common Applications of Ball Valves

Ball valves are ubiquitous across industries, thanks to their adaptability to diverse working conditions:

- Oil and Gas: Used in crude oil pipelines, natural gas distribution, and LNG terminals—fixed ball valves handle high-pressure transmission, while welded models suit underground installations.

- Chemical and Pharmaceutical: PTFE-lined or titanium alloy ball valves regulate acids, solvents, and sterile fluids, meeting hygiene standards for drug manufacturing.

- Water and Wastewater: Floating ball valves control municipal water distribution and sewage treatment, with V-port designs handling solid-laden effluent via shear action.

- Energy and Power: Regulate boiler feedwater, steam flow, and cooling systems in thermal and nuclear power plants—high-temperature alloys withstand extreme heat.

- Food and Beverage: Sanitary ball valves with smooth, crevice-free interiors prevent contamination in juice processing, dairy production, and brewing.

- Residential and Commercial: Manual ball valves shut off gas lines, HVAC systems, and plumbing, while electric models automate temperature control in smart buildings.

- Specialized Industries: Aerospace (fuel systems), marine (offshore platforms), and mining (slurry transport) rely on rugged designs for harsh environments.

Different Types of Ball Valves

Ball valves are classified by design, port size, and actuation, each tailored to specific needs:

By Ball Design:

- Floating Ball Valves: Ball “floats” to seal against the seat—simple, cost-effective for low-to-medium pressure (DN≤50 pipelines).

- Trunnion-Mounted Ball Valves: Ball anchored by trunnions—low torque, ideal for high-pressure (up to PN100) and large-diameter (DN500+) applications.

- V-Port Ball Valves: V-shaped bore for precise throttling (adjustable ratio 100:1) and shear action—perfect for viscous or particle-laden media.

By Port Size:

- Full-Port (Full Bore): Bore matches pipe diameter—minimal flow restriction, suitable for pigging (pipe cleaning).

- Reduced-Port (Standard Bore): Smaller bore—cost-effective for applications where pressure drop is acceptable (HVAC, general plumbing).

By Actuation:

- Manual Ball Valves: Lever or handwheel operation—simple, reliable for infrequent use.

- Pneumatic Ball Valves: Compressed air actuation—fast response for industrial automation.

- Electric Ball Valves: Motorized actuation—remote control for smart systems (PLC, IoT integration).

By Flow Path:

- 2-Way Ball Valves: On/off control for single flow paths—most common.

- 3-Way Ball Valves: T/L-shaped bore for mixing, diverting, or reversing flow (hydraulic systems, chemical processing).

Materials Used in Ball Valve Construction

Material selection depends on media, temperature, and pressure—key materials include:

- Valve Body:

- Stainless Steel (304/316): Corrosion-resistant, versatile for industrial and food-grade applications.

- Brass: Cost-effective, good thermal conductivity—ideal for residential plumbing and HVAC.

- Cast Iron: Durable, high-pressure resistance—used in heavy industrial pipelines.

- Titanium Alloy: Lightweight, extreme corrosion resistance—suited for marine, chemical, and high-temperature environments (price-premium).

- Seals and Seats:

- PTFE (Teflon): Chemical-resistant, low friction—soft-seal for normal temperature and low-pressure media (water, air).

- PPL (Polypropylene): High-temperature tolerance (up to 200℃)—better than PTFE for hot fluids.

- Metal (Stellite/Carbide): Hard-seal for high-pressure/high-temperature applications (steam, oil).

- Ball and Stem:

- Stainless Steel: Standard for most applications—polished surface ensures tight sealing.

- Alloy Steel: Enhanced strength for high-pressure systems.

Maintenance and Care for Ball Valves

Proper maintenance extends ball valve lifespan (up to 30 years) and ensures reliability:

- Regular Inspections: Check seals for leaks, valve stems for corrosion, and fasteners for tightness every 3-6 months.

- Cleaning: Remove internal debris and external dirt to prevent valve jamming—use compatible solvents for corrosive media.

- Lubrication: Apply lubricants (compatible with seals/materials) to stems and bearings quarterly to reduce friction.

- Corrosion Protection: Spray anti-rust agents or wax external surfaces—critical for outdoor or marine applications.

- Replace Wear Parts: Swap worn seals, gaskets, or packing annually (or as per manufacturer guidelines).

- Operational Best Practices: Avoid over-tightening levers, never use extensions (risk of damage), and test emergency shutoff functionality yearly.

Comparing Ball Valves to Other Valve Types

Choosing the right valve depends on working conditions—here’s how ball valves stack up:

| Valve Type | Key Differences | Best For |

|---|---|---|

| Ball Valves | Quarter-turn, tight sealing, low flow resistance | Fast shutoff, corrosive media, precision control |

| Gate Valves | Linear motion (gate up/down), minimal flow resistance when open | Long-term full-open use (water distribution) |

| Butterfly Valves | Lightweight, compact, lower cost | Large-diameter, low-pressure systems (wastewater) |

| Globe Valves | Linear motion, superior throttling | Steam systems, frequent flow adjustment |

| Plug Valves | Similar to ball valves but cylindrical plug | High-temperature, high-viscosity media |

Ball valves outperform others in sealing reliability, speed, and versatility—making them the top choice for most industrial and commercial applications.

Industry Standards and Certifications for Ball Valves

Compliance with global standards ensures quality, safety, and interoperability:

- API (American Petroleum Institute): API 6D for pipeline valves, API 608 for floating ball valves—critical for oil and gas.

- ANSI (American National Standards Institute): ANSI B16.34 for valve dimensions and pressure ratings—ensures compatibility with U.S. pipelines.

- ISO (International Organization for Standardization): ISO 9001 (quality management), ISO 15848 (emissions control)—global acceptance.

- AWWA (American Water Works Association): AWWA C507 for water and wastewater valves—ensures potable water safety.

- EN (European Norm): EN 13480 for industrial valves—compliance for European markets.

- Certifications like CE (European Conformity) and FM (Fire Protection) indicate adherence to safety and environmental standards.

Conclusion and Future Trends in Ball Valve Technology

Ball valves have evolved from simple mechanical components to indispensable tools in modern fluid control, driving efficiency across industries. Their unique combination of speed, sealing, and durability makes them the go-to choice for applications ranging from residential plumbing to deep-sea oil exploration.

The future of ball valve technology is shaped by three key trends:

- Smart Integration: IoT-enabled valves with sensors for pressure, temperature, and valve position—enabling real-time monitoring and predictive maintenance (reducing downtime by 30%+).

- Material Innovation: Advanced alloys and composites (e.g., ceramic coatings, carbon fiber) for extreme conditions (higher pressure/temperature, stronger corrosion resistance).

- Energy Efficiency: Lightweight designs and low-friction components to reduce energy consumption—aligning with global sustainability goals.

- Expanded Applications: Growth in renewable energy (solar/wind power fluid control) and biotech (precision pharmaceutical manufacturing) will drive demand for specialized ball valves.

With a global market projected to reach $19.6 billion by 2033, ball valves will remain at the forefront of industrial automation and fluid control innovation.

Need help selecting the right ball valve for your application? I can create a custom ball valve selection checklist tailored to your industry, media type, and pressure/temperature requirements—let me know if you’d like to get started!

Post time: Nov-10-2025