Valve ea Pneumatic Ball ke eng?

Li-valve tsa bolo ea pneumatic, tse tsejoang hape e le li-valve tsa bolo tse tsamaisoang ke moea, ke likarolo tsa bohlokoa lits'ebetsong tse fapaneng tsa taolo ea mokelikeli oa indasteri. Moralo oa tsona o monyane, ts'ebetso e potlakileng, le ho tiisa ka mokhoa o tšepahalang li etsa hore li be ntle bakeng sa mefuta e mengata ea lits'ebetso. Sengoloa sena se fana ka kakaretso e felletseng ea li-valve tsa bolo ea pneumatic, ho kenyeletsoa moralo oa tsona, molao-motheo oa ts'ebetso, mefuta, melemo, lits'ebetso, ho kenya, tlhokomelo le ho rarolla mathata. Qetellong, babali ba tla ba le kutloisiso e felletseng ea mofuta ona oa li-valve tse feto-fetohang.

1. Selelekela sa Li-valve tsa Mabolo a Pneumatic

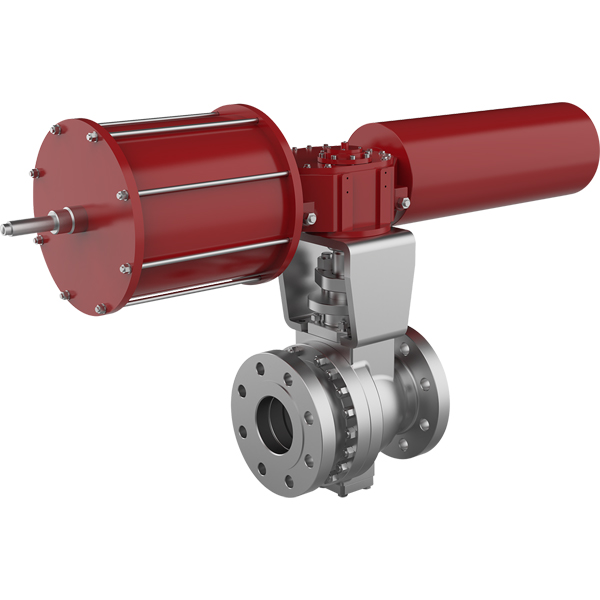

Li-valve tsa bolo tsa pneumatic ke li-valve tse sebelisang moea o hatelletsoeng e le mohloli oa matla ho laola ho buloa le ho koaloa ha valve. Li na le 'mele oa valve ea bolo, bolo (e le karolo ea ho koala valve), sesebelisoa sa ho kenya moea ka har'a moea, le lisebelisoa tse amanang le eona. Bolo e na le lesoba le chitja kapa tsela e fetang ka har'a axis ea eona, 'me ka ho potoloha bolo likhato tse 90, phallo e ka buloa ka botlalo, ea koaloa, kapa ea koalloa.

2. Moralo le Molao-motheo oa Mosebetsi

Moralo oa valve ea bolo ea pneumatic o nkiloe ho valve ea globe empa ka lintlafatso tse kholo. Likarolo tse ka sehloohong li kenyelletsa:

'Mele oa Valve: Hangata e entsoe ka tšepe e entsoeng ka tšepe, tšepe e sa ruseng, kapa thepa e 'ngoe e loketseng, 'mele oa valve o boloka bolo 'me o fana ka tsela ea phallo.

Bolo: Selikalikoe se se nang letho se nang le lesoba le chitja. Ha se potoloha ka likhato tse 90, lesoba le tsamaisana le likou tsa ho kena le tsa ho ntša metsi ho lumella phallo, kapa le sitisa phallo.

Sesebelisoa sa ho Sebetsa ka Pneumatic: Karolo ena e fetola moea o hatelletsoeng hore e be motsamao oa mechine ho potoloha bolo. E entsoe ka silindara, piston le molamu o hokahanyang.

Litiiso: Litiiso li bohlokoa bakeng sa ho thibela ho dutla. Hangata li entsoe ka thepa ea elastomeric kapa litšepe 'me li pakeng tsa bolo le 'mele oa valve.

Molao-motheo oa ho sebetsa o otlolohile: ha moea o hatelletsoeng o fuoa actuator, piston ea tsamaea, e leng se etsang hore molamu o hokahanyang o potolohe bolo. Potoloho ena e lumellanya kapa e sitisa lesoba le kenang le likou tsa ho tsoa, ka hona e laola phallo.

3. Mefuta ea Li-valve tsa Pneumatic Ball

Li-valve tsa bolo ea pneumatic li ka aroloa ho latela litekanyetso tse fapaneng:

Sebopeho: E ka ba meralo ea likarolo tse peli, likarolo tse tharo, kapa karolo e le 'ngoe. Li-valve tsa likarolo tse peli li bonolo ho li hlokomela, ha li-valve tsa karolo e le 'ngoe li fana ka ts'ebetso e betere ea ho koala.

Setiiso sa Boitsebiso: Li-valve tse koetsoeng ka bonolo li sebelisa thepa ea elastomeric bakeng sa ho koala, e loketse lits'ebetso tse nang le khatello e tlase le tse sa senyeheng. Li-valve tse koetsoeng ka thata li sebelisa ho koala ho tloha ho tšepe ho ea ho tšepe, e loketseng lits'ebetso tse nang le khatello e phahameng le mocheso o phahameng.

Tsela ea Phallo: Li-valve tse otlolohileng, tse nang le mahlakore a mararo, le tse nang le sekhutlo lia fumaneha, ho latela litlhoko tsa tsela ea phallo.

Mofuta oa Sesebelisi: Li-actuator tse sebetsang habeli li sebelisa moea o hatelletsoeng ho tsamaisa piston ka mahlakoreng ka bobeli, ha li-actuator tse sebetsang ka bonngoe li itšetlehile ka ho khutla ha selemo ka lehlakoreng le leng.

4. Melemo ea Li-valve tsa Pneumatic Ball

Li-valve tsa bolo ea pneumatic li fana ka melemo e 'maloa ho feta mefuta e meng ea li-valve:

Ts'ebetso e Potlakileng: Ho potoloha ha likhato tse 90 bakeng sa ho bula kapa ho koala ka botlalo ho etsa hore ho sebetse ka potlako.

Moralo o Monyenyane: Moralo o monyane o dumella ho kenngwa habonolo dibakeng tse thata.

Khanyetso e Tlase ea Mokelikeli: Moralo o tletseng mokoti o fokotsa ho hanyetsa mokelikeli, o fokotsa ho theoha ha khatello le tšebeliso ea matla.

Ho Tiisoa ho Tšepahalang: Litiiso tsa boleng bo holimo li netefatsa ho dutla ho fokolang, esita le tlas'a khatello e phahameng.

Ho feto-fetoha ha maemo: E loketse mefuta e mengata ea mecha ea phatlalatso, ho kenyeletsoa metsi, oli, khase le lik'hemik'hale.

Tlhokomelo e Bonolo: Mefuta e mengata e lumella phihlello e bonolo ho likarolo tsa kahare bakeng sa tlhokomelo.

5. Litšebeliso tsa Li-valve tsa Pneumatic Ball

Li-valve tsa bolo ea pneumatic li sebelisoa haholo liindastering tse fapaneng ka lebaka la ho tenyetseha ha tsona le ho tšepahala ha tsona:

Indasteri ea Petrochemical: E sebelisoa liphaepheng ho laola phallo ea oli, khase le lik'hemik'hale.

Kalafo ea Metsi: Laola phallo ea metsi le lik'hemik'hale tsa kalafo lifemeng tsa kalafo ea metsi.

Lijo le Lijo tse Nooang: Netefatsa bohloeki le ho laola phallo ea metsoako le lihlahisoa tse sebetsitsoeng.

Indasteri ea Meriana: E sebelisoa ka likamoreng tsa ho hlwekisa ho laola phallo ea mecha ea phatlalatso nakong ea lits'ebetso tsa tlhahiso.

Limela tsa Motlakase: Laola phallo ea mouoane, metsi le mecha e meng ea phatlalatso litsamaisong tsa tlhahiso ea motlakase.

Mekhoa ea ho Iketsa: E kenyelelitsoe litsamaisong tse iketsang bakeng sa taolo le tlhokomelo e hole.

6. Ho kenya le ho kenya tshebetsong

Ho kenya le ho kenya tšebetsong ka nepo ho bohlokoa bakeng sa ts'ebetso e tšepahalang ea li-valve tsa bolo ea pneumatic:

Khetho ea Sebaka: Kenya valve sebakeng se lumellang phihlello le ts'ebetso e bonolo. Netefatsa hore valve e kentsoe ka ho rapama kapa ka sekhutlo se khothaletsoang.

Tokisetso ea Phaephe: Hloekisa phaephe pele o e kenya ho thibela hore litšila li se ke tsa senya litiiso tsa valve.

Ho kenya Valve: Latela litaelo tsa moetsi bakeng sa ho kenya valve, ho kenyeletsoa le litlhaloso tsa torque bakeng sa ho kenya le ho tiisa.

Khokahano ea Actuator: Hokela actuator ho valve le phepelo ea moea. Netefatsa hore likhokahano tsohle li tiile ebile ha li na ho lutla.

Ho kenya tshebetsong: Leka valve bakeng sa ts'ebetso e nepahetseng pele o e kenya tshebetsong. Hlahloba ho dutla ha metsi mme o netefatse hore valve e a buleha le ho kwala hantle.

7. Tlhokomelo le Tharollo ea Mathata

Tlhokomelo le ho rarolla mathata khafetsa li eketsa bophelo ba li-valve tsa bolo ea pneumatic le ho netefatsa ts'ebetso ea tsona e tšepahalang:

Tlhahlobo: Hlahloba valve khafetsa bakeng sa matšoao a ho tsofala, ho bola, kapa tšenyo. Hlahloba ho dutla ho potoloha litiiso le actuator.

Setlolo: Tlotsa likarolo tse tsamaeang joalo ka ha ho khothalelitsoe ke moetsi ho fokotsa khohlano le ho tsofala.

Ho hloekisa: Hloekisa valve le actuator khafetsa ho tlosa litšila le lithōle.

Ho Nkela Litiiso Sebaka: Nkela litiiso tse tsofetseng kapa tse senyehileng sebaka kapele ho thibela ho dutla.

Ho batle phoso: Haeba valve e hloleha ho sebetsa hantle, hlahloba phepelo ea moea, mosebetsi oa actuator, le likarolo tsa kahare tsa valve bakeng sa tšitiso kapa tšenyo.

8. Mekhoa le Lintlafatso tsa Nakong e Tlang

Indasteri ea li-valve tsa bolo ea pneumatic e ntse e fetoha khafetsa ho fihlela litlhoko tse fetohang tsa lits'ebetso tsa indasteri. Mekhoa e kenyelletsa:

Lisebelisoa tse Ntlafetseng: Ntlafatso ea thepa e ncha bakeng sa litiiso le 'mele ea li-valve e ntlafatsa ho hanyetsa mafome le ho atolosa bophelo ba li-valve.

Li-valve tse bohlale: Ho kopanngoa ha di-sensor le theknoloji ya puisano ho dumella ho beha leihlo le ho laola tshebetso ya di-valve hole.

Tshebetso e Botle ea Matla: Meralo e ntlafalitsoe ho fokotsa ho theoha ha khatello le tšebeliso ea matla, e leng se tlatsetsang boitekong ba ho boloka matla.

Ho iketsetsa: Bahlahisi ba fana ka ditharollo tse ikgethileng ho fihlela ditlhoko tse ikgethang tsa tshebediso, ho ntlafatsa tshebetso ya valve le botshepehi.

Qetello

Li-valve tsa bolo tsa pneumatic keLikarolo tse feto-fetohang le tse tšepahalang litsamaisong tsa taolo ea mokelikeli oa indasteri. Moralo oa tsona o monyane, ts'ebetso e potlakileng, le ho tiisa ka mokhoa o tšepahalang li etsa hore li be ntle bakeng sa mefuta e mengata ea lits'ebetso. Ka ho utloisisa moralo oa tsona, molao-motheo oa ts'ebetso, mefuta, melemo, lits'ebetso, ho kenya, tlhokomelo le ho rarolla mathata, basebelisi ba ka netefatsa ts'ebetso e tšepahalang le e sebetsang ea li-valve tsena litsamaisong tsa bona tsa indasteri. Ha theknoloji e ntse e tsoela pele, li-valve tsa bolo ea pneumatic li tla tsoela pele ho fetoha, li fana ka ts'ebetso e ntlafetseng, ts'ebetso e ntle ea matla le likhetho tsa ho iketsetsa ho fihlela litlhoko tse fetohang tsa lits'ebetso tsa indasteri.

Nako ea poso: Mmesa-13-2025