Iyini i-Pneumatic Ball Valve

Amavalvu ebhola lomoya, eyaziwa nangokuthi ama-valve ebhola aqhutshwa umoya, ayizingxenye ezibalulekile ezinhlelweni ezahlukene zokulawula uketshezi lwezimboni. Ukwakheka kwawo okufushane, ukusebenza okusheshayo, kanye nokuvalwa okuthembekile kuwenza afaneleke kakhulu ezinhlotsheni eziningi zezicelo. Lesi sihloko sinikeza umbono ophelele wama-valve ebhola aqhutshwa umoya, okuhlanganisa ukwakheka kwawo, isimiso sokusebenza, izinhlobo, izinzuzo, izinhlelo zokusebenza, ukufakwa, ukulungiswa, kanye nokuxazulula izinkinga. Ekugcineni, abafundi bazoba nokuqonda okuphelele kwalolu hlobo lwe-valve oluguquguqukayo.

1. Isingeniso kuma-Pneumatic Ball Valve

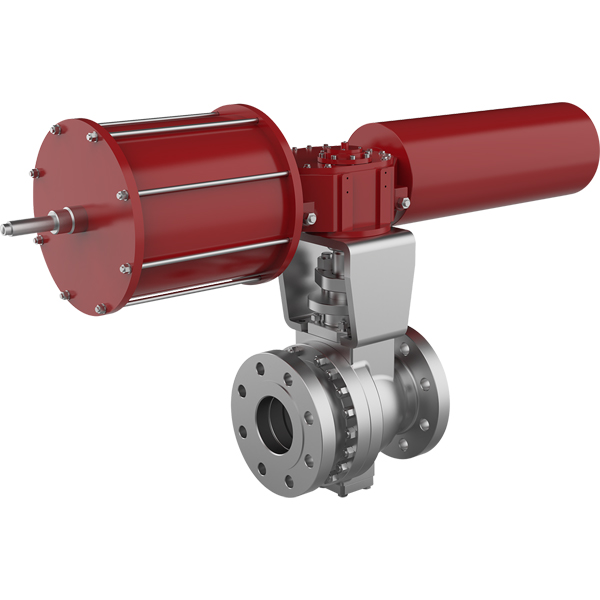

Amavalvu ebhola lomoya angamavalvu asebenzisa umoya ocindezelwe njengomthombo wamandla ukulawula ukuvulwa nokuvalwa kwevalvu. Aqukethe umzimba wevalvu yebhola, ibhola (njengento yokuvala ivalvu), i-actuator yomoya, kanye nezesekeli ezihlobene nayo. Ibhola linembobo ejikelezayo noma indlela edlula ku-axis yalo, futhi ngokujikeleza ibhola ngama-degree angu-90, ukugeleza kungavulwa ngokuphelele, kuvalwe, noma kugoqwe.

2. Isimiso Sokuklama Nokusebenza

Umklamo we-valve yebhola yomoya ususelwa ku-valve ye-globe kodwa ngentuthuko enkulu. Izingxenye eziyinhloko zifaka:

Umzimba weValve: Ngokuvamile kwenziwa ngensimbi ephothiwe, insimbi engagqwali, noma ezinye izinto ezifanele, umzimba wevalvu ugcina ibhola futhi unikeze indlela yokugeleza.

Ibhola: Imbulunga engenalutho enembobo ejikelezayo. Uma ijikeleziswa ngama-degree angu-90, imbobo ihambisana nezimbobo zokungena nezokuphuma ukuze kuvunyelwe ukugeleza, noma ihambisana kabi ukuze ivimbele ukugeleza.

I-Actuator Yomoya: Le ngxenye iguqula umoya ocindezelwe ube ukunyakaza komshini ukuze ujikeleze ibhola. Yakhiwe isilinda, i-piston, kanye nenduku yokuxhuma.

Izimbonakaliso: Izivalo zibalulekile ekuvimbeleni ukuvuza. Ngokuvamile zenziwe ngezinto ezithambile noma izinsimbi futhi zitholakala phakathi kwebhola nomzimba wevalvu.

Umgomo wokusebenza ulula: lapho umoya ocindezelwe unikezwa ku-actuator, i-piston iyahamba, okwenza induku yokuxhuma ijikeleze ibhola. Lokhu kuzungeza kuqondanisa noma kuhlukanisa imbobo edlulayo nezimbobo zokungena kanye nezokuphuma, ngaleyo ndlela kulawula ukugeleza.

3. Izinhlobo zamavalvu ebhola omoya

Ama-valve ebhola lomoya angahlukaniswa ngokusekelwe ezicini ezahlukahlukene:

Isakhiwo: Zingaba yimiklamo yezingcezu ezimbili, ezintathu, noma eyodwa. Amavalvu anezingcezu ezimbili kulula ukuwanakekela, kuyilapho amavalvu anezingcezu eyodwa enikeza ukusebenza okungcono kokuvala.

Izinto Zokuvala: Amavalvu avaliwe athambile asebenzisa izinto ezithambile zokuvala, afanele ukusetshenziswa ngomfutho ophansi kanye nokungagqwali. Amavalvu avaliwe aqinile asebenzisa ukuvala kusuka kunsimbi kuya kunsimbi, afanele ukusetshenziswa ngomfutho ophezulu kanye nokushisa okuphezulu.

Indlela Yokugeleza: Amavalvu aqondile, aqondene nezindlela ezintathu, kanye nama-engeli ayatholakala, kuye ngezidingo zendlela yokugeleza.

Uhlobo lwe-Actuator: Ama-actuator asebenza kabili asebenzisa umoya ocindezelwe ukuhambisa i-piston kuzo zombili izinhlangothi, kuyilapho ama-actuator asebenza kanye kuphela ethembele ekubuyeni kwentwasahlobo ohlangothini olulodwa.

4. Izinzuzo zamavalvu ebhola omoya

Ama-valve ebhola omoya anikeza izinzuzo eziningana ngaphezu kwezinye izinhlobo zama-valve:

Ukusebenza Okusheshayo: Ukujikeleza kwamadigri angu-90 ukuze kuvulwe noma kuvalwe ngokuphelele kwenza kube lula ukusebenza.

Umklamo Omncane: Umklamo omncane uvumela ukufakwa okulula ezindaweni ezixineneyo.

Ukumelana Noketshezi Okuphansi: Umklamo ogcwele unciphisa ukumelana noketshezi, kunciphisa ukwehla kwengcindezi kanye nokusetshenziswa kwamandla.

Ukuvalwa Okuthembekile: Izivalo zekhwalithi ephezulu ziqinisekisa ukuvuza okuncane, ngisho nangaphansi kwengcindezi ephezulu.

Ukuguquguquka: Ifanelekela izinhlobo eziningi zezinto ezisetshenziswayo, okuhlanganisa amanzi, uwoyela, igesi, namakhemikhali.

Ukulungiswa Okulula: Amamodeli amaningi avumela ukufinyelela kalula ezingxenyeni zangaphakathi ukuze zilungiswe.

5. Ukusetshenziswa kwama-Pneumatic Ball Valve

Ama-valve ebhola omoya asetshenziswa kabanzi ezimbonini ezahlukahlukene ngenxa yokuguquguquka kwawo nokuthembeka kwawo:

Imboni Ye-Petrochemical: Kusetshenziswa emapayipini ukulawula ukugeleza kukawoyela, igesi, namakhemikhali.

Ukwelashwa Kwamanzi: Lawula ukugeleza kwamanzi kanye namakhemikhali okwelapha ezitshalweni zokwelapha amanzi.

Ukudla Neziphuzo: Qinisekisa inhlanzeko futhi ulawule ukugeleza kwezithako nemikhiqizo ecutshunguliwe.

Imboni Yezemithi: Isetshenziswa emakamelweni okuhlanza ukulawula ukugeleza kwemidiya ngesikhathi sezinqubo zokukhiqiza.

Izitshalo Zamandla: Lawula ukugeleza komusi, amanzi, kanye nezinye izinto ezisetshenziswayo ezinhlelweni zokuphehla ugesi.

Izinhlelo Zokuzenzakalela: Kuhlanganiswe nezinhlelo ezizenzakalelayo zokulawula nokuqapha kude.

6. Ukufakwa Nokugunyazwa

Ukufakwa kanye nokuqaliswa okufanele kubalulekile ekusebenzeni okuthembekile kwama-valve ebhola le-pneumatic:

Ukukhetha Indawo: Faka ivalvu endaweni evumela ukufinyelela nokusebenza kalula. Qinisekisa ukuthi ivalvu ifakwe ngokuvundlile noma nge-engeli enconywayo.

Ukulungiswa Kwepayipi: Hlanza ipayipi ngaphambi kokufakwa ukuze uvimbele imfucuza ukuthi ingonakalisi izivalo zamavalvu.

Ukufakwa kweValvu: Landela imiyalelo yomenzi yokufaka ivalvu, okuhlanganisa nemininingwane ye-torque yokufaka ibholithi nokuvala.

Ukuxhumeka kwe-Actuator: Xhuma i-actuator ku-valve kanye nokunikezwa komoya. Qinisekisa ukuthi zonke izixhumanisi ziqinile futhi azivuzi.

Ukugunyazwa: Hlola ivalvu ukuthi isebenza kahle yini ngaphambi kokuyifaka. Hlola ukuvuza bese uqinisekisa ukuthi ivalvu ivuleka futhi ivala kahle.

7. Ukulungiswa Nokuxazulula Izinkinga

Ukulungiswa njalo nokuxazulula izinkinga kwandisa impilo yama-valve ebhola omoya futhi kuqinisekise ukusebenza kwawo okuthembekile:

Ukuhlolwa: Hlola njalo ivalvu ukuze ubone izimpawu zokuguguleka, ukugqwala, noma umonakalo. Hlola ukuvuza okuzungeze izivalo kanye ne-actuator.

Ukuthambisa: Gcoba izingxenye ezihambayo njengoba kunconywe ngumenzi ukuze unciphise ukungqubuzana nokuguguleka.

Ukuhlanza: Hlanza ivalvu kanye ne-actuator njalo ukuze ususe ukungcola kanye nemfucumfucu.

Ukufakwa Kwezimpawu Zokumboza: Shintsha izivalo ezigugile noma ezonakele ngokushesha ukuze uvimbele ukuvuza.

Ukuxazulula izinkinga: Uma ivalvu ihluleka ukusebenza kahle, hlola ukunikezwa komoya, umsebenzi we-actuator, kanye nezingxenye zangaphakathi zevalvu ukuze kubhekwe ukuthi kukhona yini okuvimbekile noma okonakalayo.

8. Izitayela Nentuthuko Yesikhathi Esizayo

Imboni yamavalvu ebhola e-pneumatic iyaqhubeka nokuguquka ukuze ihlangabezane nezidingo ezishintshayo zezicelo zezimboni. Izitayela zifaka:

Izinto Ezithuthukisiwe: Ukuthuthukiswa kwezinto ezintsha zezivalo kanye nemizimba yamavalvu kuthuthukisa ukumelana nokugqwala futhi kwandisa impilo yamavalvu.

Ama-Smart Valve: Ukuhlanganiswa kwezinzwa nobuchwepheshe bokuxhumana kuvumela ukuqapha nokulawula ukusebenza kwe-valve kude.

Ukusebenza Kahle Kwamandla: Imiklamo ilungiselelwe ukunciphisa ukwehla kwengcindezi kanye nokusetshenziswa kwamandla, okufaka isandla emizamweni yokuzinza.

Ukwenza ngokwezifiso: Abakhiqizi banikeza izixazululo ezenziwe ngokwezifiso ukuze bahlangabezane nezidingo ezithile zohlelo lokusebenza, okuthuthukisa ukusebenza kwe-valve kanye nokuthembeka.

Isiphetho

Ama-valve ebhola omoya akhonaIzingxenye eziguquguqukayo nezithembekile ezinhlelweni zokulawula uketshezi lwezimboni. Ukwakheka kwazo okufushane, ukusebenza okusheshayo, kanye nokuvalwa okuthembekile kuzenza zilungele izinhlelo eziningi ezahlukene. Ngokuqonda ukwakheka kwazo, isimiso sokusebenza, izinhlobo, izinzuzo, izinhlelo zokusebenza, ukufakwa, ukulungiswa, kanye nokuxazulula izinkinga, abasebenzisi bangaqinisekisa ukusebenza okuthembekile nokusebenza kahle kwala ma-valve ezinhlelweni zabo zezimboni. Njengoba ubuchwepheshe buthuthuka, ama-valve ebhola lomoya azoqhubeka nokukhula, enikeza ukusebenza okuthuthukisiwe, ukusebenza kahle kwamandla, kanye nezinketho zokwenza ngokwezifiso ukuze kuhlangatshezwane nezidingo ezishintshayo zezinhlelo zokusebenza zezimboni.

Isikhathi sokuthunyelwe: Ephreli-13-2025