I-actuator yomoya iyi-actuator esebenzisa umfutho womoya ukushayela ukuvulwa, ukuvalwa noma ukulawulwa kwe-valve. Ibizwa nangokuthi i-actuator yomoya noma idivayisi yomoya. Ama-actuator omoya ngezinye izikhathi afakwe amadivayisi athile asizayo. Avame ukusetshenziswa yi-valve positioners kanye ne-handwheel mechanisms. Umsebenzi we-valve positioner ukusebenzisa isimiso sempendulo ukuthuthukisa ukusebenza kwe-actuator ukuze i-actuator ikwazi ukufeza indawo efanele ngokwesignali yokulawula yomlawuli. Umsebenzi we-handwheel mechanism ukuyisebenzisa ngqo ukusebenzisa i-control valve ukuze kugcinwe ukukhiqizwa okuvamile lapho uhlelo lokulawula luhluleka ngenxa yokuphela kukagesi, ukuphelelwa yigesi, ukungabikho kokuphuma komlawuli noma ukwehluleka kwe-actuator.

Isimiso Sokusebenza Se-Actuator Yomoya

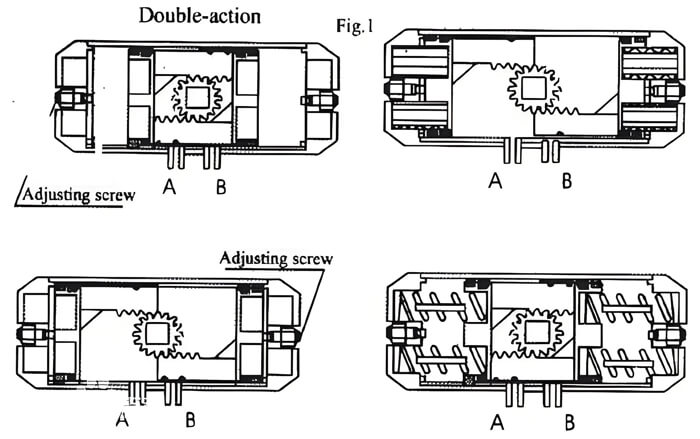

Uma umoya ocindezelwe ungena ku-actuator yomoya usuka ku-nozzle A, igesi isunduza ama-piston amabili ukuze ahambe ngokuqondile abheke emaphethelweni womabili (iziphetho zekhanda lesilinda), bese i-rack eku-piston ishayela igiya ku-shaft ejikelezayo ukuze ijikeleze ngama-degrees angu-90 ngokuphambene newashi, bese i-valve ivulwa. Ngalesi sikhathi, igesi emaphethelweni womabili e-actuator yomoya ikhishwa ku-nozzle B. Ngokuphambene nalokho, lapho umoya ocindezelwe ungena emaphethelweni womabili e-actuator yomoya usuka ku-nozzle B, igesi isunduza i-piston ephindwe kabili ukuze ihambe ngokuqondile maphakathi, kanti i-rack eku-piston ishayela igiya ku-shaft ejikelezayo ukuze ijikeleze ngama-degrees angu-90 ngokwewashi, bese i-valve ivaliwe. Ngalesi sikhathi, igesi ephakathi kwe-actuator yomoya ikhishwa ku-nozzle A. Okungenhla kuyisimiso sokudlulisa sohlobo olujwayelekile. Ngokwezidingo zomsebenzisi, i-actuator yomoya ingafakwa ngesimiso sokudlulisa esiphambene nohlobo olujwayelekile, okungukuthi, i-axis ekhethiwe ijikeleza ngokwewashi ukuvula i-valve, futhi ijikeleza ngokwewashi ukuvala i-valve. I-nozzle A ye-actuator esebenza kanye (uhlobo lokubuyela kwentwasahlobo) i-pneumatic actuator iyi-inlet yomoya, kanti i-nozzle B iyimbobo yokukhipha umoya (i-nozzle B kufanele ifakwe nge-muffler). I-inlet ye-nozzle A ivula i-valve, bese amandla e-spring evala i-valve lapho umoya unqanyulwa.

Ukusebenza kwe-Actuator ye-Pneumatic

1. Amandla okukhipha alinganisiwe noma i-torque yedivayisi yomoya kufanele ihambisane nemithetho yamazwe ngamazwe kanye neyamakhasimende

2. Ngaphansi kwezimo zokungalayishi, isilinda singena ngomfutho womoya ochazwe ku-“Thebula 2”, futhi ukunyakaza kwaso kufanele kube bushelelezi ngaphandle kokuminyana noma ukukhukhuleka.

3. Ngaphansi komfutho womoya ongu-0.6MPa, i-torque noma i-put yokukhipha yedivayisi yomoya kuzo zombili iziqondiso zokuvula nokuvala akufanele ibe ngaphansi kwenani eliboniswe ku-nameplate yedivayisi yomoya, futhi isenzo kufanele siguquguquke, futhi akukho ukuguqulwa okuhlala njalo noma ezinye izinto ezingavamile ezizokwenzeka kunoma iyiphi ingxenye.

4. Lapho kwenziwa ukuhlolwa kokuvala ngengcindezi yokusebenza ephezulu kakhulu, inani lomoya ovuzayo ohlangothini ngalunye lwengcindezi yangemuva akufanele lidlule (3+0.15D)cm3/min (isimo esijwayelekile); inani lomoya ovuzayo kusukela esembozweni sokugcina kanye nomgodi wokukhipha akufanele lidlule (3+0.15d)cm3/min.

5. Ukuhlolwa kwamandla kwenziwa ngengcindezi yokusebenza ephezulu ngokuphindwe ka-1.5. Ngemva kokugcina ingcindezi yokuhlola imizuzu emi-3, isembozo sesilinda kanye nezingxenye zokuvala ezingaguquki azivunyelwe ukuba nokuvuza kanye nokuguquka kwesakhiwo.

6. Inani lempilo yesenzo, idivayisi yomoya ilingisa isenzo sevalvu yomoya. Ngaphansi kwesimo sokugcina i-torque yokukhipha noma umthamo wokusunduza kuzo zombili izinhlangothi, inani lemisebenzi yokuvula nokuvala akufanele libe ngaphansi kwezikhathi ezingu-50,000 (umjikelezo owodwa wokuvula nokuvala).

7. Kumadivayisi asebenzisa umoya anezindlela zokubopha, lapho i-piston ithuthela endaweni yokugcina ye-stroke, ukushaya akuvunyelwe.

Izinzuzo ze-Pneumatic Actuators

1. Yamukela izimpawu zegesi eziqhubekayo kanye nokususwa okuqondile kokukhipha (ngemuva kokufaka idivayisi yokuguqula ugesi/igesi, ingamukela futhi izimpawu zikagesi eziqhubekayo). Ezinye zingakhipha ukususwa kwe-angular ngemuva kokuhlonyiswa ngengalo ye-rocker.

2. Kunemisebenzi yesenzo emihle nemibi.

3. Isivinini sokuhamba siphezulu, kodwa isivinini sizoncipha uma umthwalo ukhuphuka.

4. Amandla okukhipha ahlobene nengcindezi yokusebenza.

5. Ukuthembeka okuphezulu, kodwa ivalvu ayikwazi ukugcinwa ngemva kokuphazamiseka komthombo womoya (ingagcinwa ngemva kokwengeza ivalvu yokugcina indawo).

6. Akulula ukwenza ukulawula okuhlukaniswe ngezigaba kanye nokulawula uhlelo.

7. Ukugcinwa okulula kanye nokuzivumelanisa nezimo okuhle nendawo ezungezile.

8. Amandla amakhulu okukhipha.

9. Inomsebenzi wokuvikela ukuqhuma.

Ehlobo

Ubukhulu bokufakwa nokuxhumeka kwama-actuator nama-valve omoya kuklanyelwe ngokwezindinganiso zomhlaba wonke ze-ISO5211, DIN3337 kanye ne-VDI/VDE3845, futhi kungashintshaniswa nama-actuator omoya avamile.

Umgodi womthombo womoya uhambisana nezindinganiso ze-NAMUR.

Imbobo yokuhlanganisa umgodi ongezansi we-actuator ye-pneumatic (evumelana ne-ISO5211 standard) iyisikwele esiphindwe kabili, esilungele ukufakwa kwamavalvu aqondile noma angama-45° anezinduku zesikwele.

Isikhathi sokuthunyelwe: Feb-16-2025